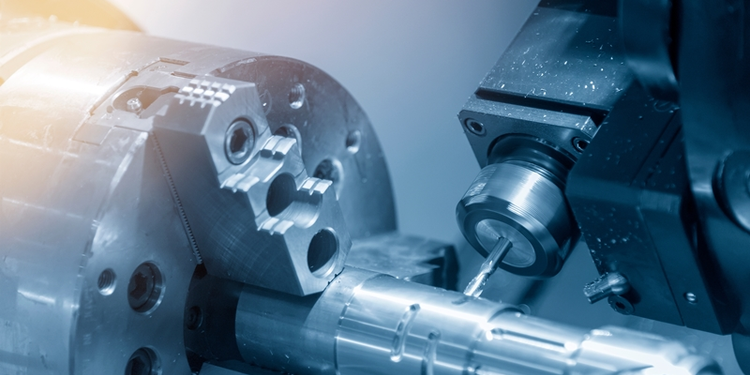

Computer numerical control (CNC) has been incorporated into a variety of new technologies and machinery. One such machine of this sort that is used for a wide array of production processes is known as a CNC lathe.

Due to technological advancements, CNC lathes are quickly replacing some of the older and more traditionally used production lathes, such as the multispindle. CNC lathes come with a number of benefits. They can be easily set up and operated. They offer tremendous repeatability, along with top-notch accuracy in production. The very act of cutting any material using a lathe machine is called “Turning”.

A CNC lathe is typically designed to utilize modern versions of carbide tooling and processes. A part can be designed for customization, and the machine’s tool paths are often programmed using the CAD or CAM processes. However, a programmer can manually design a part or tool path as well. The resulting G-Code computer file is then uploaded to the CNC machine, and the machine will then automatically produce the desired parts for which it was programmed to design.